Evo-Trend recently expanded its offering by adding a new Chinese brand – Farroad tyres – for local consumers.

Farroad Tyres Make Inroads into Malaysia

Evo-Trend Corporation (M) Sdn Bhd, a subsidiary of YHI International Ltd, is an established company in distributing tyres and alloy wheels. The company recently expanded its offering by adding a new Chinese brand – Farroad tyres – for local consumers.

According to the company, the Farroad brand is recognised by the Shandong Province as a key home-grown international private brand. The brand has good reputation and is widely accepted for its quality with its snow tyres ranked top 10 in China.

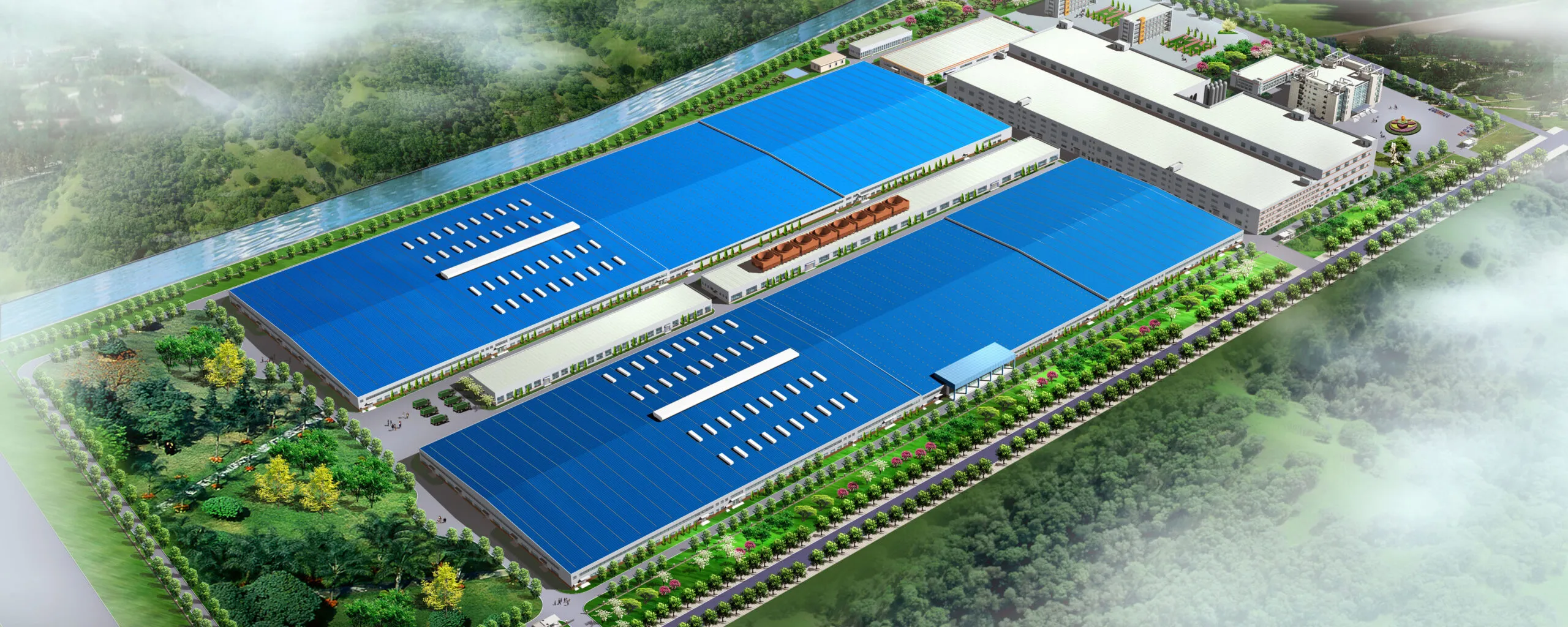

Farroad tyres are produced by Shandong Fengyuan Tire Manufacturing Co, Ltd that is located in the economic development zone of Yicheng, Zaozhuang City, Shandong. Shandong Fengyuan’s parent company – Zaozhuang Mining Group, a subsidiary of Shandong Energy Group (world top 500 corporations) – is a state-owned enterprise.

Shandong Fengyuan is a modern large-scale company that engages in tyre research and development, manufacturing and sales. With a factory area of 628 acres and total building space of 258,000 square metres, the company has more than 1,500 employees. It has an annual output capacity of 20 million semi-steel radial tyres.

The factory is well equipped with advance manufacturing equipment such as VMI building machines from the Netherlands, Steel Cord Calendaring machines from Italy and curing machines from Korea, just to name a few. It adopts new tyre manufacturing and design technology and has a 4,000-square metre high specification laboratory that complies with the ISO/IEC17025 standard. The laboratory is equipped with German SDS Shearography tyre testing machines, tyre noise testers, tyre motion measurement machines, among others. This enables the company to produce premium tyres that are of good quality and safe, low rolling resistance and low noise as well as anti-hydroplaning properties.

At present, the company’s product range includes high performance tyres, ultra-high performance tyres, 4×4 tyres (Highway Terrain /All Terrain /Mud Terrain ), drift tyres, run-flat tyres, anti-static tyres, tyres with puncture and cut protection, tyres developed especially for taxis as well as new energy vehicles, with up to 23 series and more than 600 specifications. According to Shandong Fengyuan, its tyre performance in fuel efficiency, wet grip and external rolling function complies with EU labelling standard requirements. The company also obtained many accreditations such as the ISO/TS16949 for its manufacturing plant, ISO14001 Environmental Management System Accreditation and OHSAS18001 Certification for Occupational Health and Safety System.

In addition, Fengyuan focuses strongly on technological innovations. Over the years, the company made remarkable progress in important scientific and technological fields. For instance, its new ‘one-time’ mixing method technology is recognised by the Chemical Industry and Engineering Society of China (CIESC) and its application of carbon nano-tubes in tyre production has passed the result evaluation of the China Petroleum and Chemical Industry Federation, which shows that both technologies had reached the international technological standard. The use of carbon nano-tubes in tyre production increases the strength, flexibility and anti-static nature of the tyres while enhancing their durability. The new ‘one-time’ mixing method technology and carbon nano-tubes application in tyre production also set the company apart from the others and put it in a leading position.

Apart from a nationwide sales network that achieves full coverage of the Chinese domestic market, Farroad products are exported to more than 100 countries around the world, including Europe and the US. Its products are accredited with DOT, ECE, GCC, INMETRO and CCC certification. Shangdong Fenyuan is also the OE (Original Equipment) supplier for passenger cars and new energy cars from Brilliance Auto, Zotye and BAIC (Beijing Automotive Group Co, Ltd) Group, among the many, in China.

Evo-Trend将远路轮胎列入产品组合

Evo-Trend Corporation (马)私人有限公司,YHI国际有限公司子公司,是一家著名的轮胎和铝合金轮圈分销公司。该公司近日扩展其业务,为本地的消费者新添了一个中国轮胎品牌—远路轮胎。

据该公司表示,远路轮胎品牌被山东评定为重点培育的国际自主品牌。该品牌是中国市场质量信誉双优的品牌,其雪地轮胎更是入选中国十强。

远路轮胎是由位于山东省枣庄市峄城经济开发区的丰源轮胎制造股份有限公司所制造。山东丰源母公司— 枣矿集团公司是国有控股山东能源(世界500强)的子公司。山东丰源是集轮胎研发、制造、销售于一体的现代化大型企业。公司厂区占地628英亩,总建筑面积258,000平方米,现有员工1500余人,设计规划为年产2000万条半钢子午轮胎。

该公司在技术、装备、 产品上高端定位,配置了荷兰VMI成型机、意大利钢丝压延机、韩国东河硫化机等世界一流的半钢轮胎生产线。该公司引进新的轮胎制造和设计技术,拥有先进的省级技术研发中心和专业技术研发团队,建有4,000平方米,符合ISO/IEC17025标准。该实验室选用德国SDS激光干涉仪、轮胎噪音测试机、计测动均试验机等。这使该公司能够生产出品质优良、安全、低滚阻、低噪音、抗湿滑的轮胎。

目前,该公司拥有超高性能轮胎、休旅车轮胎(高速公路/全地形轮胎/泥地形轮胎)、漂移胎、缺气保用轮胎、防静电轮胎、耐刺扎轮胎、出租车专用轮胎、新能源汽车专用轮胎等23大系列、600多个规格产品。据山东丰源表示, 产品性能在燃油经济、湿地抓地力、外部滚动功能方面均符合欧洲标签标准需求。该公司还获得了ISO/TS16949汽车安全管理体系、 ISO14001环境管理体系、OHSAS18001职业健康安全管理体系等。

此外,丰源注重科技创新,并在科学及技术领域取得巨大进展。比如,一次法混炼新技术通过国家化工学会科技成果鉴定,碳纳米管轮胎应用成果通过国家石化联合会科技成果鉴定,双双达到国际先进水平。率先采用碳纳米管材料技术,提高了轮胎的强度、柔韧性、热导率、抗静电性,增强了轮胎的耐久性。一次法混炼新技术和碳纳米管成果奠定了公司的行业引领地位。

除了在中国国内销售网络实现全覆盖,远路产品远销欧洲、美洲等100多个国家,其产品拥有DOT、ECE、GCC、INMETRO及CCC认证。山东丰源也是华晨、众泰、北汽等 汽车和新能源汽车原装配备供货商。