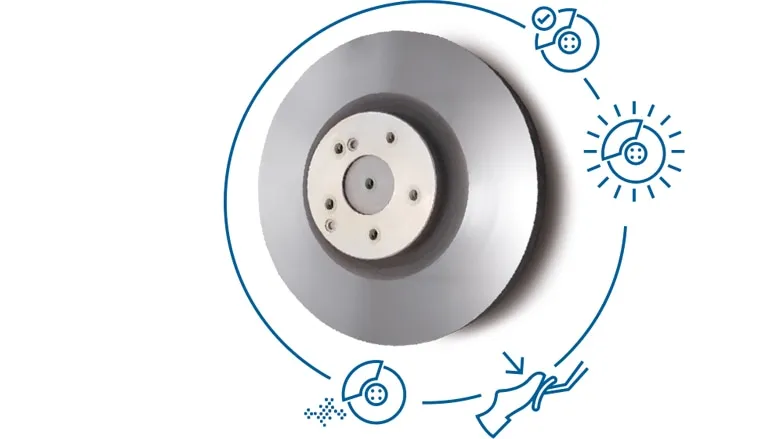

According to the State Office for the Environment, Measurements and Nature Conservation in Baden-Württemberg, Germany, around one third of the particulate emissions in road traffic is attributable to brakes and tyres, with brake dust being responsible for nearly half. However, Bosch has recently announced that a solution is on its way: with the iDisc brake disc.

Bosch Unveils iDisc to Reduce Particulate Emissions

The secret behind the iDisc lies in its hard tungsten carbide coating. This coating not only reduces brake dust, it also increases safety – especially when several braking manoeuvres are performed in succession. The iDisc is robust and has almost the same braking power as a comparable ceramic product that comes at a higher cost. In terms of price, the iDisc is roughly three times more expensive than a normal cast iron brake disc, and three times less expensive than a ceramic brake disc. The price is likely to continue falling as production volume increases.

Moreover, it is also more resistant to wear. Depending on the coating thickness, the iDisc lasts twice as long as a normal brake disc. In addition, it is less prone to scoring and corrosion, with the latter being a major advantage for electric vehicles. This is due to the fact that they have the ability to recuperate braking energy, meaning they put less strain on the brake. For this reason, when conventional brake discs are used a film of rust forms repeatedly on the friction rings. This temporarily leads to a slightly poorer response when braking, which does not occur with the iDisc.

Finally, due to the 90-percent reduction in brake dust produced by the iDisc, regular cleaning of the wheel rims – which often required highly aggressive cleaning agents – is a now thing of the past. Who knew that protecting the environment can also have very practical benefits?